Choosing the right film is crucial for high-quality Custom Direct To Film (DTF) transfers, depending on material (fabric, plastic, metal), surface texture, intended use (outdoor signage, clothing design), and resolution for optimal print results, ensuring longevity and visual appeal.

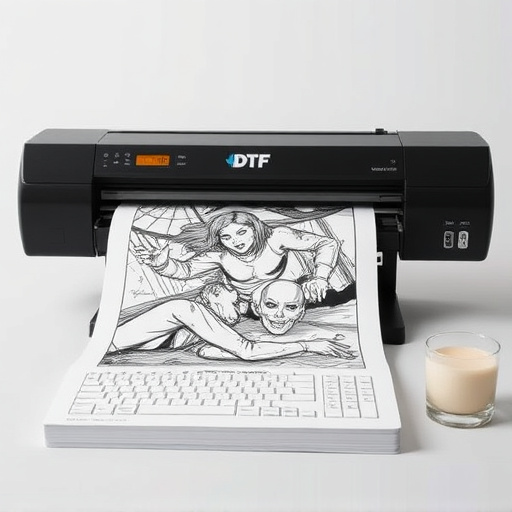

Choosing the right film for custom Direct-to-Film (DTF) transfers is paramount to achieving exceptional results. This guide delves into the essentials of DTF transfers, outlining critical factors to consider before selecting your ideal film. From understanding print quality requirements to evaluating substrate compatibility, we provide insights to ensure your custom DTF project meets high standards. By the end, you’ll be equipped to make informed decisions for optimal transfer outcomes.

- Understanding DTF Transfers: Essential Basics

- Factors to Consider for Custom Film Transfers

- Selecting the Ideal Film for Your Project

Understanding DTF Transfers: Essential Basics

Direct to Film (DTF) transfers are a cutting-edge method for printing on various materials, offering unparalleled versatility and quality. This process involves transferring ink directly onto film or other surfaces, eliminating the need for intermediate plates. Custom DTF transfers have gained popularity among professionals and hobbyists alike due to their ability to produce sharp, vibrant images on a wide range of substrates, from textiles to plastics and metals.

When choosing a film for DTF transfers, several factors come into play. The right film should be compatible with your chosen printer, offering optimal print quality and resolution. DTF transfer sheets vary in terms of material, thickness, and surface texture, each with its advantages. For instance, a high-quality polyester film is commonly used for its durability and ability to produce crisp prints on various surfaces. Additionally, considering the intended use of the final product—be it outdoor signage, clothing design, or industrial applications—is crucial in selecting the best DTF printer and film combination for long-lasting results.

Factors to Consider for Custom Film Transfers

When it comes to Custom Direct To Film (DTF) Transfers, several factors play a crucial role in ensuring top-quality results. Firstly, consider the type of film stock suitable for your project. Different films have varying characteristics, such as resolution and color accuracy, which directly impact the final print quality. Additionally, the size and format of the custom sheets for heat pressing designs onto garments are essential considerations. You’ll want to choose a size that aligns with your printer’s capabilities and the scale of your design.

Moreover, the printing method itself is a critical aspect. Modern DTF printers, such as those utilizing UV or LED technology, offer exceptional precision and vibrancy. Opting for a best DTF printer with high-resolution capabilities ensures intricate details are captured accurately. Remember that the film’s adhesion to the print surface, often facilitated by a special adhesive layer, is also vital to prevent issues like cold peel during the heat pressing process.

Selecting the Ideal Film for Your Project

Choosing the right film for custom Direct to Film (DTF) transfers is a crucial step in achieving high-quality results. The ideal film should offer excellent durability, vibrant color reproduction, and compatibility with your printing process. When selecting a film for your project, consider the material you plan to transfer onto—whether it’s fabric, plastic, or metal—as different surfaces require specific types of films. For instance, polycarbonate or PETG films are commonly used for bulk DTF shirt production due to their clarity and resistance to scratching.

For those interested in DTF printing for hoodies, a film designed for textile applications would be ideal. These films often contain adhesive backing that ensures the design adheres securely to the fabric. Additionally, the film’s thickness and flexibility should match the material it will be transferred onto to prevent bulging or cracking during the curing process. Remember, the right film choice can significantly impact the longevity and visual appeal of your custom DTF transfers.

When selecting film for custom DTF transfers, understanding your project’s unique needs and combining that with expert knowledge of available materials is key. By considering factors like resolution requirements, color accuracy demands, and intended application, you can choose the perfect film to achieve exceptional results. Custom Direct To Film Transfers offer a wide range of possibilities, allowing for vibrant prints and lasting durability, making it essential to select the right material from the outset.